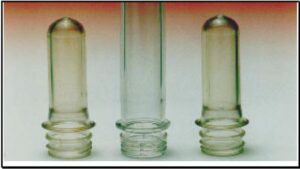

A PET Bottle manufacturer fills every Bottle with so much love and concern. A PET bottle protects the standard of drinks consumers buys. Both, the look and quality of the PET bottle are important to win the customer’s trust for your brand. And as you recognize, a quality bottle is a much bigger version of a top-quality PET Performs in Nepal. PET preforms in Nepal preset the planning possibilities, mechanical strength, and price of the bottle.

But what if you get a faulty PET? Then, the Bottle you create can have holes and marks. They burst as you are feeling your liquid, lead to dual loss. A faulty PET involves wasting time and money thus, a nightmare for the PET Bottle manufacturer. But no more. Here, we mention all types of visible defects PET Preforms can have. With this knowledge, you can discard them before blowing them into bottles. Here is the list of PET defects one must check before processing them into final products.

6 Visible Defects a Pet Bottle Manufacturer in PET Preforms must check before buying in Nepal

Bubbles in PET Preform

Air bubbles get trapped within the preform walls. This gas enters the PET preforms when the Bottle manufacturer is giving the raw plastic an appropriate shape. The bubbles go unnoticed while you buy the PET. But once you blow the Bottle, the Bubble gets trapped. The bottles with Bubbles will either develop a hole or cannot bear the load. They could not get the right shape, i.e., develop a shrinkage. You cannot use such a Bottle for the packaging.

Air bubbles get trapped within the preform walls. This gas enters the PET preforms when the Bottle manufacturer is giving the raw plastic an appropriate shape. The bubbles go unnoticed while you buy the PET. But once you blow the Bottle, the Bubble gets trapped. The bottles with Bubbles will either develop a hole or cannot bear the load. They could not get the right shape, i.e., develop a shrinkage. You cannot use such a Bottle for the packaging.

How to solve: First, you’ll increase the oven ventilation of the preform. Change within the heat by turning off lamps while loading the perform. The use of CB2 cooling shields is additionally useful.

How to detect: You would see small oval pores once you see the PET Preforms in Nepal with naked eyes. The Bubble is with a magnification glass. These sorts of Bubbles aren’t seen within the entire batch but are observed on a few PETs every batch. If you get tons of Bubbles within the PET tubes, you would get to change the PET preform manufacturer.

Unmelts in PET Preform

PET preforms in Nepal are made from very tiny plastic granules called plastic resin pellets. These resin pellets need remelting and molding before they’re mixed with other PET-forming materials. But sometimes, the PET has resin pellets that are partially or completely unmelt. Incorrect heat profiles and incorrect blowing settings leads to unmelts. In such cases, the preforms would reject the blowing process. Even after full blowing, these unmelt resin makes the Bottle look unappealing.

PET preforms in Nepal are made from very tiny plastic granules called plastic resin pellets. These resin pellets need remelting and molding before they’re mixed with other PET-forming materials. But sometimes, the PET has resin pellets that are partially or completely unmelt. Incorrect heat profiles and incorrect blowing settings leads to unmelts. In such cases, the preforms would reject the blowing process. Even after full blowing, these unmelt resin makes the Bottle look unappealing.

How to solve: Reduce heat within the body and improve neck temperature. Increase the neck heat and replace the non-return valve at the preceding station. You would reduce pre-blow pressure and check cooling shield settings.

How to detect: You would see a raised portion within the neck or base area. These pellets caused uneven surfaces within the PET perform body. Short shots or cuts

As a manufacturer, you would possibly notice that the PETs are incompletely filled. While such incomplete fills can occur in any part of the Bottle, you can mostly observe it in the neck area. These PET preforms in Nepal look usual once they are first brought. But then, the Bottle is hard to blow or shows the symptoms of a corked neck or leakage. The leakage could destroy the whole consignment of cartons. These cuts are caused by the wrong heat profiling and poor shield positioning.

Short shots or Cuts in PET Preform

As a PET Bottle Manufacturer in Nepal, you would notice that the PETs are not filled completely. While such incomplete fills can occur in any part of the Bottle, it’s usually observed at the neck area. These PET preforms in Nepal look normal once they are first brought. But then, the Bottle is hard to blow or shows the symptoms of a corked neck or leakage. The leakage could destroy the whole consignment of cartons. These cuts are caused by the wrong heat profiling and poor shield positioning.

As a PET Bottle Manufacturer in Nepal, you would notice that the PETs are not filled completely. While such incomplete fills can occur in any part of the Bottle, it’s usually observed at the neck area. These PET preforms in Nepal look normal once they are first brought. But then, the Bottle is hard to blow or shows the symptoms of a corked neck or leakage. The leakage could destroy the whole consignment of cartons. These cuts are caused by the wrong heat profiling and poor shield positioning.

How to solve: Avoid contamination within the PET preform manufacturing plant. Maintaining the temperature is equally important. Also, you would like to blow molds.

How to detect: These cuts are often hardest to detect with the naked eyes. Only big cuts are visible as an extended or short mark. The main portions appear only if the Bottle is fully blown. You would use polarized light to look at these cuts in detail

Moisture marks in PET Preform

These parallel or random rings are usually seen across the body of the perform. The light-colored marks are very hard to detect within the first look. But once you take such PET tubes to the secondary stage, they cannot be blown. Such preforms show uneven heating and bursts before they are crammed with the air. The marks are very small and the Bottle somehow gets its shape. But eventually, they develop holes, which will cause even more issues.

These parallel or random rings are usually seen across the body of the perform. The light-colored marks are very hard to detect within the first look. But once you take such PET tubes to the secondary stage, they cannot be blown. Such preforms show uneven heating and bursts before they are crammed with the air. The marks are very small and the Bottle somehow gets its shape. But eventually, they develop holes, which will cause even more issues.

How to avoid: Clean the oven shield and check the air diffuser for any sort of damage. You want to make sure that the oven shields aren’t touching the preform in any way.

How to check these defects: checking these marks with naked eyes in two to three PET preforms in Nepal helps to determine the quality in all batches. If these sorts of defects are seen often, you would like to vary the PET preforms supplier in Nepal. Since these marks are hardly visible to the naked eyes, devices like Polariscope strain are extremely useful.

Black specks in PET Preform

Contamination exists in our environment. But a slight carelessness of the PET manufacturer causes the addition of random foreign particles found on the preform body. This contamination appears because of the black spots which may be seen from the surface. Such PET preforms in Nepal of degraded material within the cavity produces a poor looking Bottle. Usually, such preforms can be blown, but the blown Bottle shows the unpleasing appearance of the liquid that’s packed in these bottles. Since these sorts of Bottles might reach the market, they create a negative image of the brand.

Contamination exists in our environment. But a slight carelessness of the PET manufacturer causes the addition of random foreign particles found on the preform body. This contamination appears because of the black spots which may be seen from the surface. Such PET preforms in Nepal of degraded material within the cavity produces a poor looking Bottle. Usually, such preforms can be blown, but the blown Bottle shows the unpleasing appearance of the liquid that’s packed in these bottles. Since these sorts of Bottles might reach the market, they create a negative image of the brand.

How to avoid: The resin pallets won’t make the PET completely free from all types of pollutants. Clean the general working system frequently and make the working zone free from any sort of contamination.

How to check these defects: You can’t see this black space until you examine each PET performs carefully. If your PET manufacturer used the initial resin that was contaminated, the entire batch might need to be rejected. This is often seen after you blow the Bottle. Black specks in bottles are also caused by overheating, excessive shearing of resin, and mishandling of the Bottle.

Discoloration in PET Preform

Among different PET defects, an abnormal yellow tint or discoloration is one of the major issues. Such color is spread throughout the whole preform and is observed in an entire batch. This is often likely to have degraded/ low-quality staples within the PET-making industry. The utilization of non-food grade R-pet (Recycled PET) can also be the cause of the paleness of the whole Bottle. Since these products are made in a big batch, you would get a whole box of pale PET perform and can’t notice it. Such discoloration (often bluish)can also appear if the resin molecule is stretched beyond its natural capacity.

Among different PET defects, an abnormal yellow tint or discoloration is one of the major issues. Such color is spread throughout the whole preform and is observed in an entire batch. This is often likely to have degraded/ low-quality staples within the PET-making industry. The utilization of non-food grade R-pet (Recycled PET) can also be the cause of the paleness of the whole Bottle. Since these products are made in a big batch, you would get a whole box of pale PET perform and can’t notice it. Such discoloration (often bluish)can also appear if the resin molecule is stretched beyond its natural capacity.

These PET preforms in Nepal get rejected during the blowing procedure as they can’t withstand the warmth. But if they convert into the Bottle; IV gets degraded to release AA (Acetaldehyde). This Acetaldehyde, when it gets to the Bottle, spoils the taste and quality of the content. It harms the health of the purchasers.

How to avoid: Using high-quality resin and setting in right point temperature is the most. One may additionally increase the air ventilator and use clean blowers.

How to detect: You’ll compare the color of such batch with the previous batch to detect the faults. You can also compare the color of the bottle after the PET perform is blown.

How to prevent from getting faulty PET Preforms in Nepal?

Don’t get trapped by the seller’s sweet words. Usually, a PET preform looks fine until the Pet preform manufacturer is trying to blow them. In most cases, the faulty PET preforms fail when you blow them. Or, they could have bend neck, holes, and large cuts even after blowing. Having one or two faulty PET preforms in Nepal among a hundred is normal. But if the problems start to rise, it will create an issue.

So, what should you do before getting trapped by the PET preform manufacturer?

- Visual examination of a couple of PET preforms in Nepal in every batch may be a great way to start with.

- You’ll also need to get a Polariscope strain or Laser device to see if the faulty PET preforms in Nepal. These devices detect the faults listed above and show the standard of the PET preforms in Nepal.

But do remember that faulty PET isn’t the sole reason your bottles get damaged. There could be something wrong while you’re blowing it or filling the liquids. So first, fix these issues within the factory itself. But if the matter exists then, do check the quality of the PET preforms. But it’s impossible to examine every PET preforms in Nepal in a batch.

If many bottles cannot be blown or get holes or the wrong color after being blown, it’s time to vary your supplier.

Conclusion

Before you rush to shop for PET preforms in Nepal, do your homework to check these six defects. Adopt any inspection method you’re conversant in. But only pick the initial product that provides you with excellent quality. Getting a PET preforms in Nepal only from the trusted PET preform manufacturer in Nepal is a simple way to cut the prices and luxuriate in a fair deal on your PET bottles.

For more information visit us on Youtube.