Are you looking into starting your own business, and have finally decided to start a PET Bottle Manufacturing Business? One of the most lucrative businesses in the market at the moment happens to be PET Bottle Preform Manufacturing Business. PET or Polyethylene Terephthalate is a form of polyester molded into plastic containers or bottles. In this blog, you will learn the minimum requirement you need to have to start a PET Bottle Manufacturing Business.

Before moving on to the PET bottle preform manufacturing process, one must know what a PET bottle is? PET is a Polyethylene Terephthalate, a strong, stiff synthetic fiber made with ethylene glycol and terephthalic acid.

Aside from being lightweight, the PET containers don’t react with food, making them ideal for food, beverage, medicine, and packing other elements.

General Plastic Industries has been in the Pet Preform and Pet Bottle Manufacturing Business since 2004, and have been selling quality PET Preforms and Bottles to more than 200+ customers. Over the years through experience, we have learned that installing a PET Bottle manufacturing business without prior knowledge of the minimum requirements or information regarding the type of machinery leads to inadequate quantity and poor-quality PET Bottles.

Here, we have compiled a list of all minimum requirements for the PET Bottle Preform Manufacturing process.

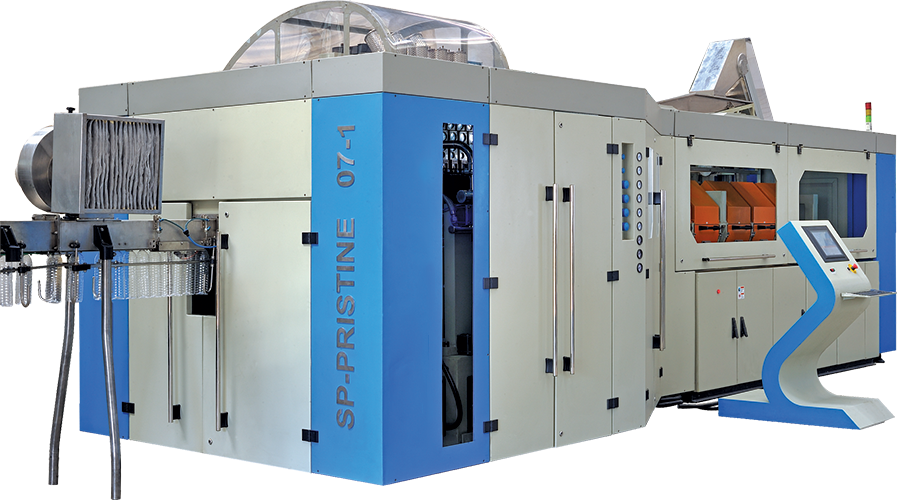

PET Bottle Manufacturing Blow moulding machine:

The Most important machine which will give you the quality and quantity you desire. We recommend you to buy a quality machine which will give you higher productivity and quality and over a period of time cover the higher cost paid by you for the machine.

Before buying the machine the bottle requirement and the estimated budget need to be calculated to decide the type of machine required to be purchased, a Semi-automatic machine or a fully automatic Machine. Where Semi-automatic machine is comparatively cheaper and good for lower capacity production and fully automatic machines are expensive and have higher production capacity.

Factory Space:

PET bottles that are lightweight use a lot of space for storage. So adequate space is required to keep the raw material and finished goods.

Servo Stabilizer:

We always recommend our customers buy a servo stabilizer for their blowing machines. This will keep the power input stable and prevent uneven heating which is one of the major causes of bottle rejection.

Preform Supplier:

Another important factor that needs to be considered is the Preform Supplier. The supplier needs to provide you with consistent quality preforms at the right price. As a mineral water supplier, you know that during the summer season the demand is high, you also need to take into account whether this supplier can meet that demand.

Chiller:

Most blowers disregard the requirement of cooling lines, but you should not make the same mistake, for consistent quality bottles and fast production this is a must. Sometimes even a cooling tower also works depending on your demand

Compressor:

A blowing machine requires a high-pressure Air compressor for blowing the Bottles and a low-pressure air compressor for operating the machine. The minimum requirement is a 30HP Motor High-pressure compressor for blowing bottles.

Air Dryer:

To make a quality bottle this Machine is used to remove all the moisture from the air used to blow the bottles.

To start a profitable PET Bottle Manufacturing business, you have to take the above requirements into account and our suggestion is to go for quality machines from known branded suppliers so that you get adequate production and quality and over a longer period earning you profits.

Starting a business is always challenging, and having a PET Bottle Manufacturing business is no different. Hence, we recommend considering all the requirements before getting into this business.

Keep yourself updated about all the quality machinery from guaranteed suppliers to ensure quality and quantity during the production. If you face some problems along the way, consult with an expert regarding the PET bottle preform manufacturing business.

Feel free to contact us on Facebook.