Acetaldehyde(AA) is a by-product of the PET manufacturing process. It is produced when PET is heated to a high temperature to produce bottles. Many beverages and foodstuffs contain natural acetaldehyde.

The quantities of acetaldehyde that may migrate from PET into bottled water are harmless, although they may cause the water to have a slightly fruity off-taste. The consumer may be able to taste it when the concentration exceeds 0.02 mg of acetaldehyde per liter or more than 3 ppm of AA.

Based on consumer’s acceptance and local regulation, this is something that should be avoided in some countries whereas it is well accepted in others. PET bottle manufacturers have worked closely with the bottled water companies to optimize the PET bottle production process to minimize levels of acetaldehyde migration.

In this blog, we will discuss how are PET Preforms made, methods used during PET preforms Manufacturing, How Acetaldehyde is generated during the Preforms making and Blowing Process, its effects on human beings, and Methods to Minimize Acetaldehyde(AA) contamination in PET bottles.

If you are PET Blowers and care about your consumers we suggest you read this blog till the end. This blog will be very helpful for you to understand all the facts about Acetaldehyde and its contamination Effects. First and foremost let’s discuss what are PET Preforms and how are they made.

What are PET Preforms and how are they made?

The abbreviation PET stands for polyethylene terephthalate, a polymer that, from a chemical point of view, is a polyester. Much of the PET produced today is used to produce fibers either for industrial or clothing applications. It is usually mixed with natural fibers like cotton and wool. Polyesters were first manufactured in the 1930s, for use as synthetic fibers. In the 1970s, a production process for PET bottles was developed. PET bottles were initially used for soft drinks, but gradually their use for bottled water was expanded.

A preform is an intermediate product that is subsequently blown into a polyethylene terephthalate (PET) container. The PET bottle is produced in the injection process originally in the preform of the bottle. During this process the polymers soften with temperature, normally pass through several stages of heating the material, followed by mechanical forming. Several methods are used in the production of plastic parts such as extrusion, injection molding, blow molding, etc.

They are produced through two processes, injection and blow. Depending on the final part application during the process of injection molding, which consists essentially in heating and softening of the material grain in a heated cylinder and its subsequent injection at high pressure to the mold, where it cools and takes final shape.

Injection molding is the most widely used method in the manufacture of plastic products. It has high efficiency and manufacturability. The molding process includes three stages: filling, cooling, and extraction. The first stage begins by filling the mold cavity with the molten polymer at an injection temperature.

The polymer melt is packed into the cavity at a higher pressure to compensate for the anticipated shrinkage as the polymer cools (solidifies) in this cooling phase. When the part is sufficiently rigid to be extracted from the mold, care is redoubled because this phase directly affects and especially productivity and quality molding.

The injection molding process is controllable in the specified limits. The injection molding can be manufactured with a single cavity or a larger number of similar or dissimilar cavities. The cavities are interconnected through flow channels or runners, which direct the flow of molten plastic material into the cavities.

The cooling time is important in the manufacturing process. It is important that the injection cycle is from the start of injection until opening the mold for extracting the workpiece. This time is associated with the solidification temperature.

The cycle of injection of the preform is performed as follows: mold closing; injection unit of advancement; Injection; Repression; Retreat (machine gun); Dosage; Opening the mold and extraction of the piece. Other processes for the production of PET containers can be made by three methods.

Injection stretch blow: the preform produced is then reheated and stretched and molded into final packaging. This process is called ISBM (Injection Stretch Blow Molding) – Injection molding, stretching, and blowing process of a stage;

Injection blow: the preform is produced, then reheated and blown to stay in the shape of the final package. This process is called IBM (Injection Blow Molding) injection and blow-molding.

Injection: a preform is produced and stored and then forwarded to the area for blowing production of the package.

Preforms vary in neck finish, weight, color, and shape. Preforms are specifically designed to meet the needs of customers in different market segments. A preform is made by a “finish design” (bottleneck), which will not change in the blowing process. The main features of the preform depend on the finish design bottleneck’s diameter and thread type. These features determine the kind of screw bottle cap and the use of the bottle (for still water, sparkling water, oil, milk).

On the other hand, the tubular structure, will form the bottle in the blowing and molding processes and it determines the basis weights of the final product; diameter, length, and shape are the key elements that give the main features to the blown container. The PET polymer, used for the production of preforms doesn’t have a color. It’s almost transparent, but once mixed with coloring additives, it can have different shades of color according to customer requirements.

Generation of Acetaldehyde in manufacturing the resin.

In the production of PET resin, AA is formed during the polymerization stage, which takes place in the melt phase. The amorphous grain obtained at this point may be between 50 ppm and 100 ppm AA as temperatures and residence times used in the process. This resin is post condensed in the solid-state up to a molecular weight suitable for manufacturing bottles. During this step, the AA diffuses out of the grain along with the glycol being driven by process N2.

Thus, the AA in the PET bottle out of the solid post-condensation step achieves lower residual AA levels of 3-4 ppm. Depending on the desired specification for the beverage manufacturer it could reach levels below 1 ppm. The resin is intended for transformers, which are mainly subjected to the injection blow molding process. In this process, the resin is re-melted in the injection phase, then taking place again degradation of the resin. Thus generating AA.

Generation of acetaldehyde in the molding process

In the resin molding process (PET) the melting temperature is a key control of the generation of variable formation of acetaldehyde (AA) is in the process consisting essentially of softening the material in a heated cylinder. The production of PET resin for packaging can be produced with low levels of residual acetaldehyde (AA). This waste is generated during the melting of the polymer in the injection molding of the preform.

Therefore, it is important to control the injection process in which the polymer is subjected to high temperatures for prolonged periods of fusion besides the residence of the fusion temperature.

We have to consider other relevant factors which are responsible for acetaldehyde levels found in PET containers. Such as the type and formulation of the resin, type of equipment, thread profile design of the barrel of the injection machine, and processing condition Initially. Only the glass kept this property as required to properly package the carbonated and meet the manufacturer’s requirements for packaging these products while maintaining the desired transparency.

PET bottles obtained in injection and blowing process, allowed to gather optical properties, mechanical and permeability required for preparation of these carbonated beverages or non. The flavors and aromas in beverage groups may be altered by the presence of (AA) from the environment may be, the product itself, and/or the packaging material used.

From the point of environmental contamination arising view, can be diverse sources such as combustion of wood, coffee roasting, acetic acid, and vinyl acetate production from ethylene, among others. The synthesis or the formation in the food itself comes also in different ways, mainly by oxidation of the primary alcohol ethanol or ethyl and fermentation processes for the production of foods and beverages.

Concern about the presence of acetaldehyde in PET packaging is due to the taste change that may cause the packaged product. For example, colas and mineral water in which its flavor is directly affected by the presence of AA. The non-carbonated mineral waters are more sensitive, resulting in a low perception threshold to the taste in the range of 20 ppm to 40 ppm AA, depending on the water composition.

Acetaldehyde is a byproduct of PET degradation, formed when PET polymer is subjected to high temperatures, typically used in manufacturing and processing when the polymer is heated above the melting temperature and maintained its high residence time. Two mechanisms are proposed for AA formation by thermal decomposition of PET.

The first is the thermal decomposition of the hydroxyethyl end group, the second considers that degradation occurs preferably by random scission of the molecular chain of the PET with the breaking of ester bonds. These degradation chains are formed with acids and vinyl terminal groups that can react in various ways, eliminating AA.

Why is the minimization of Acetaldehyde (AA) is necessary for PET Preforms?

If you are a PET Preform blower then it is very important to reduce the Acetaldehyde contamination in your bottle. Traces of acetaldehyde can migrate from the PET bottle wall into natural mineral water. The main goal in preform and bottle manufacturing is to reduce the acetaldehyde concentration in PET.

From migration theory, the bottle wall concentration of acetaldehyde is directly proportional to the migration under the same storage conditions. This means that the reduction by a factor of two results in half of the migrated amount of acetaldehyde into bottled water.

2-Aminobenzamide, also known as anthranilamide, is the most popular acetaldehyde reduction additive and is called an acetaldehyde scavenger. This is used in PET preform manufacturing. This additive reacts chemically with acetaldehyde to form a non-odorous and higher molecular weight substance.

As with any other additive, 2-aminobenzamide must be approved for application in PET bottles. Specific migration limit of Aminobenzamide of 0.05 mg per kg food is to be controlled in routine tests by the mineral water filling company.

Is it deadly for your mineral water bottle consumer?

The effect of acetaldehyde on your health depends on how much AA is in your body, how long you were exposed, and how often you were exposed. The way it affects you will also depend on your health. Another factor is the condition of the environment when you were exposed.

Acetaldehyde promotes adduct formation, leading to functional impairments of key proteins, including enzymes, also DNA damage which promotes mutagenesis. Some of the acetaldehyde enters your blood, damaging your membranes and possibly causing scar tissue. It also leads to a hangover and can result in a faster heartbeat, a headache, or an upset stomach. The brain is most affected by acetaldehyde poisoning. It causes problems with brain activity and can impair memory.

Acetaldehyde (ethanal) is an aldehyde that is highly reactive and toxic. The World Health Organization considers acetaldehyde to be a Class 1 toxin (human carcinogen). The main source of acetaldehyde is the consumption of alcohol. Acetaldehyde is found in nature in many foods such as ripe fruits, cheese, and heated milk.

Acetaldehyde is primarily used to produce other chemicals, including acetic acid and disinfectants, drugs, and perfumes. IT is even able to cross the blood-brain barrier. Research shows that Acetaldehyde was present in rat brain 120 hr after a single dose of acetaldehyde.

We are sure that after reading this blog till here you are now well educated about what is PET Preforms, how are PET Preforms made, methods used during PET preforms Manufacturing, how Acetaldehyde is generated during the Preforms making and Blowing Process, and its effects on human beings. Now let’s discuss factors to consider and Methods to Minimize Acetaldehyde(AA) contamination in PET Preforms and Bottles.

How to Minimize AA contamination?

AA is generated at significantly elevated temperatures. Thus, control of the injection process is critical to control the AA generation in the production of bottles. On the other hand, the blowing stage has virtually no effect on the formation of AA, since it works at warmer temperatures.

Thus, to reduce the generation of AA from the resin during the injection of the preform, it is advisable to keep the polymer melt at the lowest temperature possible for the minimum time, with minimum shear.

The concentration of AA in the preform increases in proportion to the drying temperature, the barrel, and the mold. But only adjust the barrel temperatures and mold channels does not guarantee that the temperature of the molten polyester stays fit. The viscous melt is also heated by friction with the barrel, the screw, and the distribution channels.

This friction is much dependent on the viscosity of the molten resin as the type and speed of the thread. Besides the heat generated by friction, shear mechanically breaks the polymer molecules, thereby forming more hydroxyethyl end groups, which, in turn, make more AA.

some of the possible causes are listed in order of likelihood and/or ease of correction:

1. Barrel / hot runner heater overriding:-

Make sure all the heating zones are operating correctly. This will Reduce the Increased AA problem.

We Should Also check that:

-Thermocouples are seated correctly & are free of any kind of damage.

-Clip-on ammeter and infrared thermometer should be used to ensure that all the heaters are drawing correct amperage and temperature.

-All SSR’s are switching correctly when commanded by the heat controller.

-check all the Wire connections are tight.

2. Melt temperature settings too high

We can reduce the risk of hydrolysis causing lowered I.V and degradation of the material that can lead to increased A. A . level by Running the machine with the lowest practical melt temperature .

Using a melt temperature that is too low can cause problems such as: -Broken low shear bolts.

-Damage to screw tip.

-Increased crystallization

-crystals do not get melted properly so they become “seed crystals”.

-Very long screw charge time.

-Poor mixing of the material.

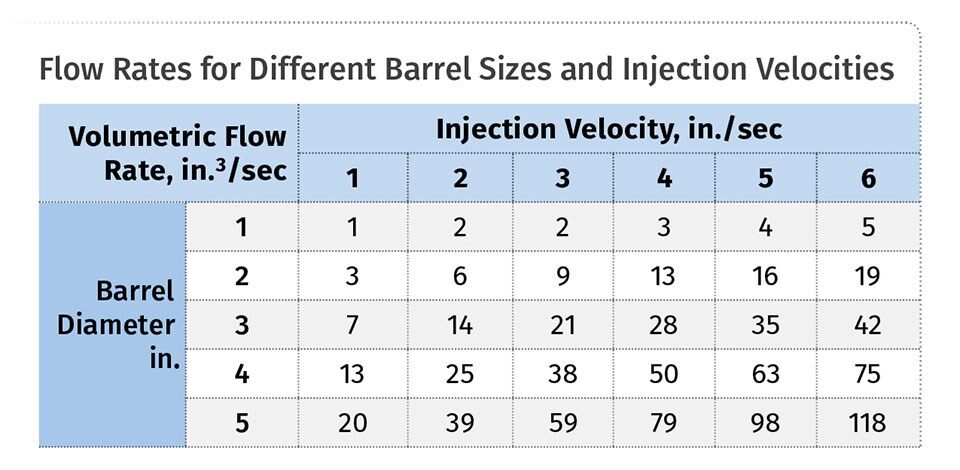

3. Injection velocity too high

Shear is a major factor affecting overheating of the material and I.V. reduction. Keeping the injection velocity low will reduce the shear that occurs in the material therefore reducing velocity will protect the PET resin from excessive damage.

When working with the hot preform method, the injection velocity will also make a significant difference to the material distribution in the finished container. Filling slower means that the preform will be hotter when the mold opens and its temperature balance will also have changed.

Typically, the shoulder area will become relatively hotter than the base area giving more stretch at the top of the preform. Excessive injection velocity can also disturb the alignment of the injection core, especially if the design is long and thin. Reducing the injection velocity will also have the effect of making the holding time shorter since the V/P time will increase

4. Screw rpm too high

If the speed of screw rotation is reduced then this will prevent excessive shear and associated frictional heating from occurring. The end result will be better control of acetaldehyde and protection of the material I.V.

5. Insufficient temperature/airflow in the dryer

A faulty dryer will lead to hydrolysis of the material in the barrel of the machine. This will cause lowered I.V. of the material and lowered I.V. is the major cause of bad quality in preforms and bottles. Maintaining the dryer in optimum condition will allow the molding machine to perform at maximum efficiency and quality. More than 60% of all PET processing-related faults can be traced back to the dryer.

Airflow – There should be nothing causing a restriction in the process and regeneration of airflow. This is the most important parameter

Temperature – check the Regeneration Temperature which should be around 200~230ºC depending on the maker. Also, Process Temperature should be in the region of 145~170ºC Depending on the resin supplier and the drying time.

Time – Time is critical. Always Calculate (or measure) the time the material is in the hopper, this should be at least 3½ – 4 hours.

Dewpoint – consult the maker’s manual before assuming an error exists as we know that Correct dewpoint may vary according to the manufacturer of the dryer.

6. Incorrect choice of raw material

Check whether your supplier is using Rpet (Recycled PET) – Many of the so-called cheap preform suppliers use Recycled pet.

Although it is widely accepted today the Recycled pet available in Nepal / India is not food grade and does have any IV certification. When mixed with virgin PET most of these preforms are degraded and thus emit high AA content. Also, Recycled pet is costlier than virgin material and hence it is suggested to avoid preform manufacturers using Recycled pet.

Copolymer should be used for better results. The use of Comonomers such as CHDM or isophthalic acid lowers the melting temperature and reduces the degree of crystallinity of PET. Thus the resin can be formed at lower temperatures and/or with lower force.

7. Worn/damaged injection screw

Damaged or worn injection screws and with old design may not be plasticizing the material correctly and maybe creating excessive shear.

If all the above possible causes are well observed and prevented, then AA contamination can be reduced. If you are a PET Preform Blower company and you care about your Consumers, Acetaldehyde is one of the danger factors and should be always kept minimum.